If you are interested in starting a T-shirt business, it is important to have some knowledge before jumping in. In this article, we will provide you with basic tips and ideas you should know about T-shirt design. After reading the eight tips below, you will find it much easier to communicate with your suppliers, who will do what they can to support you.

The History of T-shirts

The T-shirt has been a staple of American fashion for over a century. It all started in the early 1900s when the U.S. Navy issued white, crew-neck T-shirts to its sailors. The T-shirt quickly became popular among civilians and was worn as an undershirt for work and casual wear.

In the 1950s, the T-shirt gained popularity as a symbol of rebellion among teenagers. James Dean famously wore a plain white T-shirt in the movie “Rebel Without a Cause,” which helped cement the T-shirt’s place in pop culture.

Understand the factors affecting the price of T-shirts

1. Fabric weight and price

When it comes to the manufacture of t-shirts, one important factor to consider is the weight(thinner OR thicker) of the fabric. Typically, t-shirts are made from KNIT fabric, specifically single jersey fabric and rib. In China, suppliers sell knit fabric by weight, measured in kilograms per roll. The question then arises – how do you convert the fabric price from weight (kg) to length (meter)?

To make this conversion, you can use the following formula: Kilogram to meter conversion = 1000 / (fabric width in meters) / (fabric weight in grams). For example, if the fabric price is 7 dollars per kilogram, the fabric width is 1.85 meters, and the fabric weight is 180 grams, the calculation would be as follows: 1000/1.85/180=3. This means that one kilogram of fabric equals three meters, and so the price per meter would be &7/3=$2.34.

However, it is important to note that the actual weight of the fabric may be slightly heavier than what is marked by the fabric suppliers. This is due to the stretching and retracting of the fabric during the shaping process. As a result, the actual meters of fabric per kilo may be less than expected. For instance, if the fabric is marked as 180 grams, but upon weighing, it is found to be 190 grams, then it is actually 2.85 meters per kilo. This would cause more money on price per meter increase to $2.46.

Understand fabric weight of t shirt

It is crucial to understand that the fabric weight in grams refers to the square meter weight of the fabric, not the weight of the t-shirt. Sometimes clients mistakenly refer to the total weight of the t-shirt when asked about fabric weight requirements. However, a standard short sleeved t-shirt usually weighs less than 1 meter. long sleeved t shirt cost about 1 meter.

To recognize the fabric weight in grams, it is essential to keep in mind that the thicker the fabric, the higher the gram weight. For a summer t-shirt, it is generally appropriate to choose a weight between 160-200 grams.

2. Fabric width

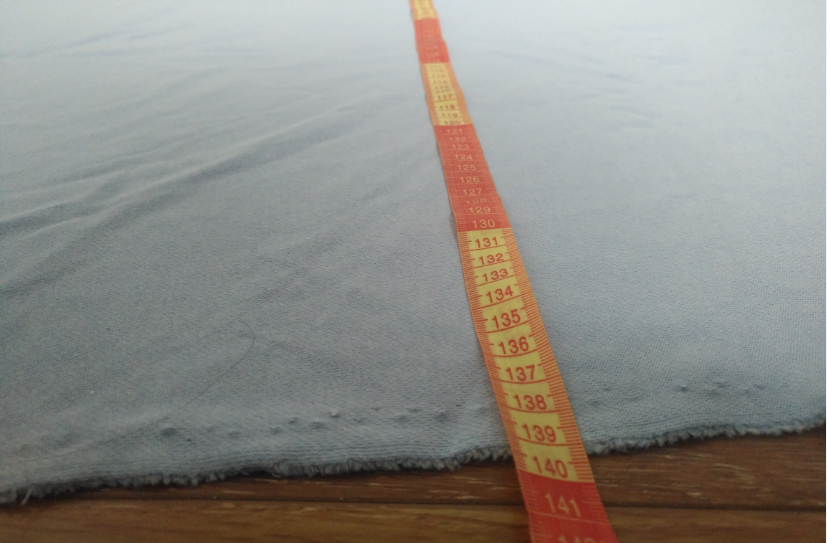

Understanding Fabric Width

Before diving into the relationship between fabric width and price, it’s essential to understand what fabric width is. Fabric width refers to the distance between the two selvages, or finished edges, of the fabric. Typically, fabric width is measured in inches or centimeters.

The cost of fabric is directly proportional to its width.

However, the utilization rate of the fabric differs depending on its actual size. The wider the fabric, the lower the cost per meter. In case two fabric suppliers are offering the same fabric at the same price, it is advisable to choose the wider one.

Typically, the width of knitting fabric ranges from 175-185CM, although some fabrics have a widest range up to 210cm. However, factories tend to avoid using such fabrics because their cutting tables are usually only 200cm long.

Some fabrics tend to roll up on both sides, and workers need to cut small portions before cutting the main fabric. It is advisable to trim off a little bit at the sides every 1-2 meters. Lighter fabrics tend to roll up more, which increases the time required for cutting and may affect their usage.

3. Size

The size of knitted t shirts can be affected by the shrinkage that occurs during the manufacturing process. One brand may have different sizes from other brands. Typically, the fabric is pre-shrunk after being returned to the factory, but some fabrics may still experience shrinkage even after pre-shrinking. To prevent further shrinkage, certain fabrics are sent to a washing factory where they are washed and will not shrink any further.

To ensure that the perfect t shirt is the correct size, it is important to allow the fabric to fully contract before taking measurements. Some factories will leave the fabric lying flat for 2-3 days before making t shirts to help with this process. Additionally, workers must be careful when handling the fabric, as pulling it too tightly or too loosely can cause the size to become smaller or larger respectively. Experienced workers often use a wooden ruler to gently guide the fabric to the correct tension.

4. Color

When purchasing fabric in large quantities, it is important to remind your suppliers to provide fabric of the same color and loft. Failure to do so can cause a real headache, as the dyeing process may not produce identical colors due to the variation between batches. Generally, up to 95% of the colors will match, but there may be slight discrepancies. Fabric suppliers typically have multiple colors and lofts in their warehouses, and if you don’t specify the same loft, they will likely choose the easiest option available.

Clients may request custom t shirt colors, which is possible if you meet the minimum order quantity of 1000kgs per color. You can select colors from the Pantone colors chart. However, if the fabric is not in stock or part of the new collection, they may require a higher minimum order quantity. For custom colors, several color lap dips will be provided for you to choose from, while for fabric in stock, you will typically receive a fabric swatch or color card. It is worth noting that lighter colors tend to be more stable, while dark blue and black are less so. These colors may need to be redyed, so be mindful of their color fastness.

5. Fabric Composition

Most T shirts are made from cotton fabrics. Cotton t shirt can absorb moisture and feel comfortable, while PThe majority of T-shirts available in the market are made from cotton fabric. Cotton is preferred because it can absorb moisture and feels comfortable against the skin. On the other hand, polyester is cheaper but less comfortable to wear. However, there are now functional fabrics that have become popular due to their comfortable, breathable, and sweat-absorbent properties.

6. Garment dye(Dip dye and tie dye)

Dip dye and tie dye have become increasingly popular in recent years. In 2019, colorful tie dye fabric for knit jersey was a hot-selling item, and it was available in almost every shop in the Zhongda fabric market, which is the biggest wholesale professional fabric market in southern China.

However, due to the manual operation and the varying sizes of clothing, the color and position of each piece may differ slightly, and the defective rate is relatively high. The production cost is also expensive because it requires a significant amount of manual labor and must be dried naturally using hangers. As a result, production time is typically longer, usually taking 7 days or more, and the minimum order quantity is often more than 300 pieces.

Tie dye t shirt

Dip dye t shirt

7. Logo embroidery or printing

In addition to blank t-shirts, most clients prefer to add some graphic elements to their shirt designs, such as a logo, animal, flower, letters, cartoon, and more. It’s easy to get t shirt design ideas with graphic designer through internet. You can also use adobe illustrator to custom t shirts. Certainly that you can get great t shirt design from designers with high resolution image quality in latest trends.

T-shirt printing is a more popular choice than embroidery due to its lower cost, faster delivery,multiple printing colors, and numerous printing options and printing method to choose from, such as direct-to-garment printing (DTG printing), screen printing, and heat transfer printing. Embroidery in small logo common placement on left or right chest area.

However, with repeated washing and wearing, the colors of the printed design may fade or crack. Embroidery, on the other hand, typically lasts longer and does not experience color fading or cracking.

You can learn more about different embroidery use on t shirts in other articles here.

Also different way of prints here.

8. Garment wash

When it comes to

When it comes to garment wash, it is important to consider the shrinkage rate of the fabric both horizontally and vertically before cutting. It has been observed that the horizontal shrinkage is typically between 4% to 8%, while the longitudinal shrinkage ranges from 3% to 6%. To obtain more precise data, it is recommended to inspect each roll of fabric. This will enable the clothing manufacturer to create more accurately sized garments.

Furthermore, it is crucial to consider the color of the fabric. Generally, it is advisable to move from dark to light shades. For instance, darker colors such as black shirts can be used to create acid wash effect like snow black or gray shades.

By taking into account these factors, garment manufacturers can ensure that the clothes they produce are of high quality and meet the expectations of their customers.

The End

If you have any questions on the t shirts, or need to custom your own clothing line, please feel free to contact us.