There are many different print ways on apparel, can you finger them out? I think you must at least have printing t shirts, guess which way is that?

In this article, you will learn 3 big different t shirt printing methods, at least 10 kinds of printing method. Let’s see now!

1. Silkscreen printing

According to the types of printing effect and process, it can be divided into: water-based printing, plastisol printing, oil–based printing, discharge printing, puff printing, thermal discoloration, water discoloration, foil, bronzing, flocking, etc.

The silk-screen print process is mainly divided into manual printing and machine printing. In recent years, machine printing is more and more popular. The principle of machine printing is the same as that of manual printing.

Silk-screen printing does not have much requirements on the fabric, nor does it need to do the pre-treatment process like some digital printing. It is good at various forms of printing Especially 3D, thick plate, bronzing, flocking, cracks, etc. which is difficult to achieve with digital printing.

Silk-screen printing uses two methods: indirect screen printing and stencil printing. It uses the unique technology of screen-making, wherein a film is made and put into a square screen. The part of the film with holes allows ink to pass through, while the other part remains closed. During printing, the screen printing ink paste passes through the screen printing holes and penetrates the fabric’s surface, thus printing the ink on the clothes.

The Printing method is indirect screen printing and stencil printing: Through the unique t shirt printing technique of screen-making, firstly need to make film, then put the film into the square screen, the film part with holes can go through the ink, and the part without is closed. When printing, the silkscreen printing ink paste can penetrate the surface of the fabric through the screen printing holes, so that the printing ink is printed on the clothes.

Water-based printing

Only suitable for light-colored fabrics, it’s soft touch and has high color fastness! It is commonly used on cotton fabrics. The main component of the water-based ink is water modulation, water is also a colorless transparent liquid. It is unlikely to cover darker fabrics, so it is difficult to do on dark fabrics print.

Plastisol printing

Mostly used in darker-colored fabrics and polyester fabrics.

Disadvantages: This type of printing without stretch, The printed pattern cracks after stretching. It feel hard and smooth on surface, not breathable, especially the pattern size for print is big.

Advantage: You can print any color you want on the dark fabric, and it can use almost all kind of fabric. Especially good in printing cartoon patterns.

Supplement: properly plastisol ink mix some foaming materials in the glue, and after fully mixing it evenly, you can also make a three-dimensional foaming effect and imitation flocking snowflake effect.

Oil–based printing

Oil-based printing, Usually used on synthetic materials with relatively smooth and shiny surfaces, such as nylon, polyester, etc. The oil-based ink is delicate and with elastic, after print hand feeling is soft and works good on stretch fabric. Mostly used on brand and quality clothing, cost is higher. The printing is much better and long lasting than the other two.

Comprehensive advantages of garment silk-screen printing: The cost is relatively low, the printing process is simple and convenient, and for some rush orders, small quantities of garment printing orders, it can be the best choice. The silk-screen printing process is widely used in T-shirt printing, cultural shirt printing, and advertising shirt printing.

Adding extra special ink and process silk-screen printing can also make:

Foil print

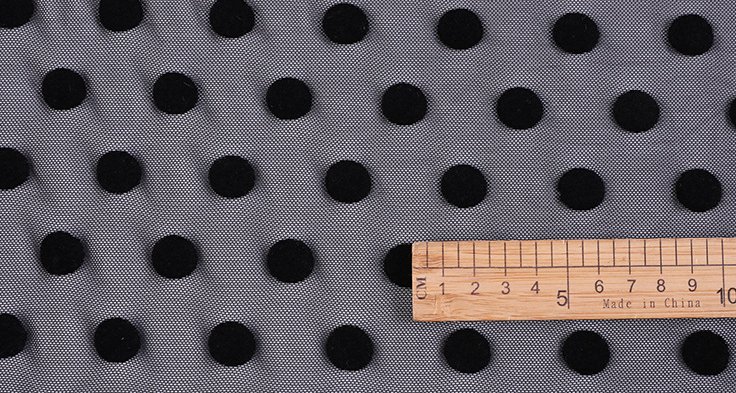

Flocking

3D Puff printing

Thick plate printing

Discharge printing

Silicone printing and other printing.

2. Digital printing

Digital printing commonly referred to DTG printing (Direct-To-Garment printing). The existing pattern is converted into a digital form and input into a computer through a scanner (or directly designed and drawn in software such as AI and Coreldraw). It is edited and processed by color separation drawing system, and then the micro-piezo inkjet nozzle controlled by inkjet printer directly sprays the special ink onto t shirts, after the color mixing the graphic come. (Through the color management You See What You Get). Digital printing process has a wide color gamut, bright colors, high precision, delicate images, and soft touch.

Digital printing effect looks like high-end printing, breaking through the color limitation of traditional textile printing and dyeing patterns, especially in the printing of high-precision patterns such as color gradients and moire, etc. Digital printing technique have unparalleled advantages, machine operation work, less workers, high production efficiency, fast turn around time on mass production.

At present, digital inkjet inks are mainly divided into reactive print, acid print, dispersion print, pigment print and oily inks print.

Reactive printing

Mostly used on pure cotton T shirts, it’s friendly to human oz free. However, there are processes of steaming, washing, etc. in the production process. Will cause certain pollution to the environment. At present, it is gradually shrinking under the trend of environmental protection.

Disperse printing

is mainly used on polyester and chemical fiber fabric. It is to spray the dispersed ink directly on the fabric to form a color. At present, dispersion direct injection technology is used in the process of pure cotton direct injection.

Acid printing

is mainly used for silk and wool. More common in the application of scarves, cheongsam and other products.

pigment printing

Can be used on any fabric. However, the color fastness and washing fastness are different. It looks like be a substitute replacement for reactive printing, without steaming and washing, and good to the environmental protection. At present, it is mainly use cotton fabric, the patterns produced are bright and beautiful, very soft to touch, and very high precision. The pigment printing supports various output software and file formats. It can be completed in one step and is easy to print. But require quality import ink, cost is relatively expensive, or the printing is easy to fade. The general steps of the pigment printing process are: image processing-> pre-spraying treatment -> direct-jet printing-> solid color, which seems simple, but it also has some know-how.

The advantage of digital printing in high-precision, large-scale fabrics that can be printed. The printing process is convenient and fast, no need film. It feels lighter and breathable. Disvantage is cost a bit high.

3. Transfer printing

Heat transfer printing

Heat transfer method is Light fastness, water fastness, strong color fastness; can be under the sun for a long time without deformation or discoloration, with a very rich color expression, can be used for character pictures, small text, letters, LOGO, etc. It’s widely use for polyester t shirts.

Hot stamping print

The graphic is print on a transparent plastic paper with glue, put the t shirt pieces with the special heat transfer paper in the right placement, go through heat press machine with high temperature(depending on the fabric composition and print size, the time and temperature is different.), after a few seconds take the plastic paper off, the print is stamping on the clothes.

It’s widely use nowadays, can use on any fabric, many small business owners and start up businesses buy stock blank t shirts, then use hot stamping print for their logo. They are widely used in print on demand service, any quantity can print, no MOQ require.

Dye Sublimation print

The dye sublimation printing process belongs to the transfer printing techniques. It is an eco-friendly and sustainable option of current printing process. This simple production process involves the use of digital printing technology to design various styles, colors, and patterns, as required by the customer. The pattern is printed on the transfer paper, and then transferred from the printed paper to the fabric through the high-temperature 150℃ ~ 230℃through the diffusion into the fabric to achieve coloring. They are mostly use on all over printing and fabric printing, low cost but durable designs in bulk orders.

The sublimation process does not require water or sewage, the process is very short and fast. The flexibility is strong, It is a finished product after printing, Not require pre-treatment processes such as steaming and washing; It has bright colors, transfer paper without contaminating the fabric; Less defected rate, multiple color patterns can be printed at one time during transfer without registering prints.

The disadvantage is that the sublimation printing process mainly processes polyester material.

The End

It is important to note that the quality of the final print depends not only on the printing method but also on the t shirt design, fabric, and other factors. It is always recommended to consult with a professional printing company before choosing a printing method for your apparel. We can customized your own print on clothes. If you have any questions about t shirt printing method, please feel free to contact us.