Although T shirts are the most basic and simple designs in our daily dressing, they take up a great share in the fashion industry, it’s a must have essential item in our daily life.

T shirts can be a good beginner products for new business clothing starters with so many aesthetics, functions and customer demand – it’s easy to find a niche field of the market to sell to.

Before you start the clothing business for t shirts, it is basic to know how the factories produce t shirts and how much investment fund you should expect. I create this article to explain in detail how t shirts are made in factories and give you a basic idea of the cost on t shirts production. Let’s take a clear look below.

Step 1. Confirm the details of the t shirt you want to produce

First of all, what details does the factory need to know about the t shirts before they start to produce? The following is the information you should provide to the factory.

Specification of t shirts include size chart

T shirts can be designed for different people and different purposes, children’s t shirts, women’s s t shirts, and men’s t shirts, the length and the width size various. So the most basic thing is to tell the factory the specifications.

The fabric of the t shirts

The natural dyes raw materials for t shirts can be 100% cotton, organic cotton, modal, polyester, CVC, bamboo, Tencel, comb cotton, cotton/polyester blend and so on. Each of them has its own advantages and characteristics.

But the most common t shirts in the market is mainly cotton or cotton blending. Such as 100% cotton and 95%-97% cotton. Polyester is much cheaper than cotton, i will suggest to use nature fabric to make which is more comfortable and durable.

For your customized t shirts, you can provide the t shirts factory fabric composition and rough fabric weight. For example, if you want 95% Cotton 5% Spandex single jersey 180g, the factory will choose right fabric to make t shirts according to your requirements.

Alternatively, you can let the factory know what kind of t shirt you want, such as more soft hand feeling, more colorful colors, more nature fabric or more competitive on price, the factory will source different types of fabric to meet your requirements. After confirm the fabric, they will buy mass production materials.

Step 2. Made the t shirt pattern and size

How to make pattern

The pattern maker will draw the pattern design according to your size specification, with computer pattern program software like ET, usually the pattern maker have many years of experience in apparel manufacturing. They know how to adjust the fitting on different parts like armhole and neckline.

How to grade size:

Usually the t shirts will have different sizes to meet different body shape, size range from XS-3XL. The pattern maker will grade the size by computer program, they will put the cm or inch for each size, then adjust it by experience.

Note: Pattern is the most important part of the whole t shirt process, it’s the main factor how you fit while wearing, specially armhole and neckline.

Step 3. Cut into pieces

After grade the size, The quantity for each color and size may be different. Like this way we can not just print out each size then cut in average, the pattern maker need to set different sizes into different sections according to the quantity, this is why sometimes the quantity is not 100% same as your order quantity, it will be more or less due to the fabric rolls, factory will use up the rolls to save the wastage.

It’s very important that the usage or the percentage of the fabric in real use, because it’s the main cost for the fabric, the more percentage use means the more lower cost on fabric. This is the reason why factory will ask size specification before they quote you the price, without the size measurement they will not get more detail cost on fabric.

The cutting workers will check the sample, quantity and sizes carefully before they cut, any questions they will ask to the pattern maker. Then they will put one layer of the paper first on the cutting table, then the fabric length require on the pattern, each layer need smooth and flat without wrinkle. This part need at least 2 workers work together, cutting for 20 layers and 100 layers different just around 2 hours, so the workers prefer to cut the big quantity, because mostly the salary is count by cutting pieces. By counting into average cost for each piece, the more quantity the more cheaper. After cutting, they will divide and select each size to small batches, the same color same size in one pack, sewing workers can work more quickly and know the size to put the right size label.

It is worth mentioning that T shirt fabric is not sell by meters, they are selling by rolls, also all the other jersey or knit fabric, like fabric for hoodie, sweatshirt and gym wears. if cut by meters the cost for the fabric will be around 3 times more than the roll price.

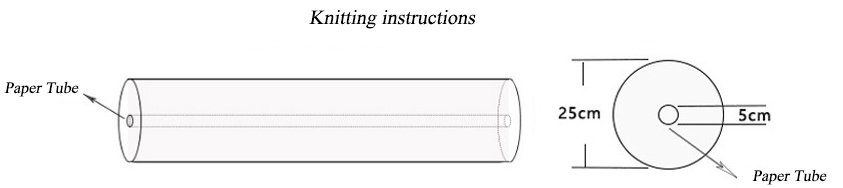

One roll fabric usually from 23 to 28 kgs, usually one roll of t shirt fabric in 180g can make around 100-110 pcs women’s short sleeve t shirt, around 90 -100 pcs of men’s short t shirt, around 180-200 pcs of kid’s short t shirt.

Step 4. Screen printing or embroidery logo

As regular t shirts are with screen printing or embroidery logos, after cutting the factory will send the pieces need to screen printing or embroidery before sew together. Usually the factory will outsource this part, send to their partners to handle the logo.

Step 5. Sew the t shirt

Sewing Worker will sew the t shirt pieces into a final t shirt. Usually 4 kinds of machines will be use on making shirt.

- Over lock stitching machine (side seam, armhole, neckline)

- Twin stitching machine(bottom, cuff)

- Top stitching machine(neckline, label)

- specially designed machines for specific workmanship, like twisting stitch.

How T shirts are made in factories, sewing process as this:

- Assemble the front and back seam lines by over-lock stitching machine, put washing instruction or care label now.

- Assemble armhole and sleeve.

- Hem stitching, turn 2.5 cm in, superimposed seam with twin stitching.

- Sleeves stitching. Short sleeve t shirt same as hem turn 2.5 cm in. Long sleeve t shirt usually use rib cuff to tighten on wrist.

- Stitching shoulder seams.

- Attaching neck band. Usually use match color rib neckline, It is elastic and will not deform so easily.

- Put the labels, neck brand logo and size label.

It’s the human control the machine, so sewing head and sewing thread may be different, skilled workers can make versatile garments, sew faster and better quality each needles.

Step 5. Inspect quality and cut the threads

There will be one round quality inspection after the sewing. The purpose of this process is to check the t shirts in good sewing so that they can move to next stage. Cut the spare threads to make tidy and clean.

Step 6. Shape the t shirts

Each t shirts neckline and armhole will be put into molds and pressing hard for iron, this process to ensure the shape of the neckline in center and good shape to pack.

Step 6. Final inspection and pack the t shirts

The last but not the least step is to pack the t shirts with exquisitely designed labels and packaging. At the same time as packaging, workers will also carefully check the quality of the t shirts to see if there are any defectives like dirty inks, trims, labels, stitching etc.

Regular t shirts packaging

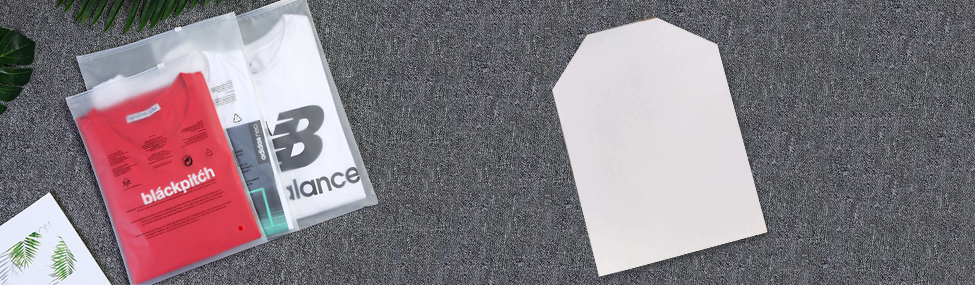

For the most common packaging, the workers will use the pin or string to put the tag go through the neck label, fold the t shirts then see the neck and upfront. Then the t shirts will be packed into a transparent poly bag.

Cardboard packing

Sometimes the clients need to pack with cardboard behind, in order to present the shape and pattern of the t shirts to customers more intuitively.

The End

Thanks for your reading, I hope this article about how t shirts are made in factories can be helpful to your business. If you have some confuses, you can leave a comment and we would love to give you the answer. You can also submit an inquiry if you have the plan to wholesale or customize t shirts.