Premium quality can only be born by combining skilled work with the best materials available.Each material used in making our uniform is carefully selected by our uniform experts to ensure it’s green & of top-quality.At Heyday, for uniforms production, we only use:

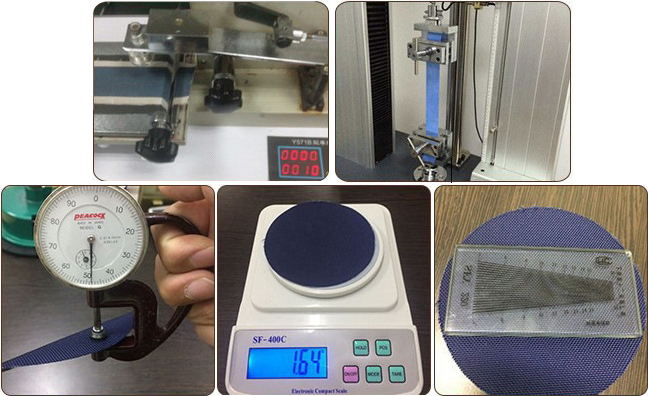

All materials will go through strict in-house inspections. Only qualified fabrics, trims, and labels will be put into mass production.

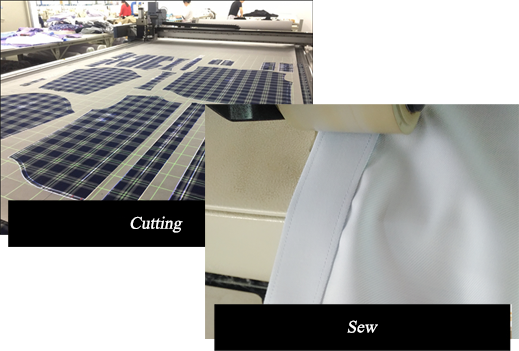

Pre-shrink clothing fabric before cutting ensure the size is stay same after washing, specialy fabric with cotton and lycra.

Checking fabric layer by layer, then cut into right size, quantity and color.

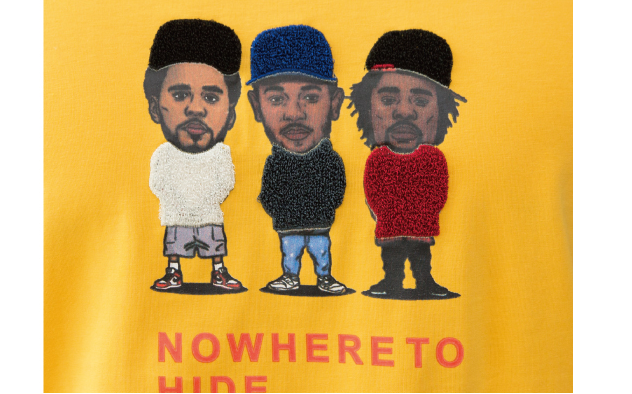

If the clothes have other craftsmanship like print, embroidery, laser cut, ruber ect, need to do in this pieces part NOT in finish clothing.

Use different machines sew the pieces into a final uniform. All the seams need to qualify to the requirements.

Important part on size and outlook, make sure all seams flat and good shape.

Every pieces clean the threads, dirty inks, Qualify uniforms will pack into bags, custom bags and package are available.

Weigh the fabric to ensure the weight is qualified to requirement.

Double check the color(side to side, front to bottom) is qualify to the color shape.

Check the fabric not have holes, dirty inks and others

Check the right size, right color and fabric.

Check each cutting pieces in right size and quantity, a full right quantity piece.

Check the sewing machines are right thread and needles.

Measure to see if the right size as required.

Check if the color is right according to bulk fabric.

Carefully inspect the surface to see if there are any scratches & stains.

Final check to ensure the clothes sizes are right to size label.

Inspect carefully to see if the logo is attach complete & printed/embroidery as per requirements.

Check if the clothes are correctly packed in perfect condition.

Tell us about your needs, We will contact you within 24 hours.